Benefits of Modular design:

QUICK DELIVERY

The skeleton of the Panel is made from just two profiles, the Vertical and the horizontal members. The rest of the partitions, base plates, base channels and doors are all standardized for different sizes in multiples of 30 mm in X, Y and Z axis. All these components are stocked based on the concept of minimum reorder volumes. Hence the deliveries are practically possible for quick delivery

FLEXIBLE

Scores of standardized components go to make the Modular design. These are versatile in the features of inter-changeability; can accommodate late minute component additions, changes and even have the doors reversible from left to right and vice versa! Any make of electrical switchgear can be accommodated with ease and extensions to the panels can even be done at site with precision. The panels can be made in Form 1 to Form 4b with all variations including single and double front.

COST EFFECTIVE

Standardization helps scaling. The result is economies of scale. The beneficiaries are our customers and end users. Further the profiles are not only with 3 / 4 bends but also punched with 6.5 dia holes at 30 mm interval delivering modularity to our switchboards. This also renders the Panels rugged, sturd and reliable yet being light weight. Less material, more technology, less cost & less scrap!

LV switchboard ‘Lini Type’

Technical Data

| Conformance to standards | IEC 60439- 1&2 & IS 8623 |

| Short circuit withstand (Icw) - main bus | 50kA / 1sec / 105kA peak |

| Short circuit withstand (Icw) - neutral | 30kA / 1sec / 63kA peak |

| Short circuit withstand (Icw) - earth | 30kA / 1sec / 63kA peak |

| Degree of protection (IP) | IP 4X, 5X, X2 |

| Ambient temperature | 40º C / 45º C / 50º C |

| Temperature rise | As per IEC 61439 -2:2011 |

| Rated insulation voltage | upto 1000V |

| Rated operational voltage | Mupto 690V |

| Main busbar rating | upto 3200A |

| Busbar execution | Interleaved / non-Interleaved |

| Busbar options | Copper / aluminium |

| lnfeed termination | Cable / bus ways / busduct |

| lnfeed entry | Top / bottom |

| Cable feeder access | Front / rear |

| ACB cubicle | Single tier |

| Form of seperation | upto form 4B |

| Standard height | 2085mm & 1875mm |

| Standard depth | 420mm / 600mm / 1020mm / 1200mm |

| Standard colour shade | RAL 7035 / RAL 7032 |

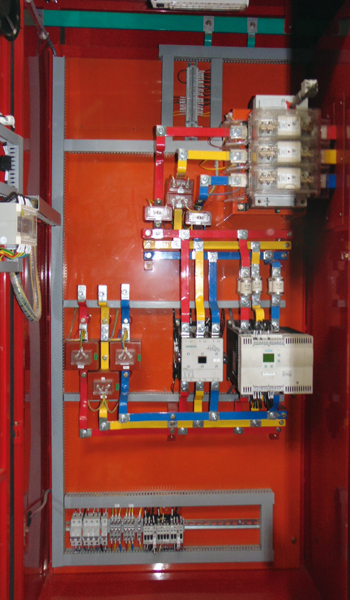

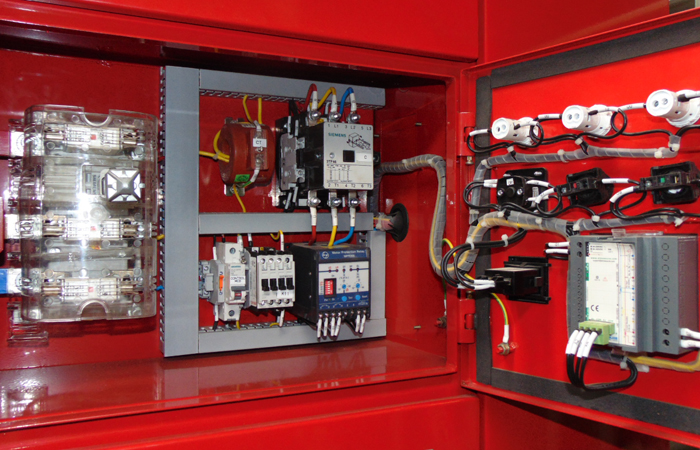

Salient features of the panels

Use of non-hygroscopic SMC supports for Bus bar for adequate mechanical and electrical strength to withstand specified full current.

Panels are totally enclosed, dust proof and vermin proof, and fully compartmentalized, cubicle design and modular construction. The covers and doors are well gasket with neoprene rubber gaskets so as to obtain dust proof enclosure.

The panels are manufactured with separate Bus bar chamber isolated from Unit feeder chambers and Cable Alleys. This provides extra safety for working personnel.

The panels are made of 2/1.6mm thick CRCA / Special grade GI sheet steel for robust construction. The doors are provided with concealed hinges for better aesthetic appearances.

All sheet metal work is processed using CNC Laser machines and CNC Press Brake machines, resulting in desired accuracy.

Standardized & Optimized design and size of Panels, compartments, Bus bar Chamber and Cable alley.

The panels are treated for de-greasing, de-rusting, Phosphating and Passivation by adopting eight tank processes as per the Indian Standard Specification before powder coating with epoxy based powder.

All Control and Power wiring terminals are brought out in the Cable Alley for easy cable termination.

All Power and Control wiring is done using numbered ferrules of proper size and quality at both ends for identification. The wiring is neatly bunched and kept in the PVC trunking and closed by a cover for a clear wiring.

All Bus bars are insulated with heat shrinkable PVC sleeves and all the live parts are shrouded to avoid accidental contact.

Technical Specifications:

The Power and Motor Control Centers are metal clad totally enclosed dust and vermin proof modular construction, self supporting, floor mounting, air insulated cubicle type for use on 415 Volts 50 Cycles AC supply.

Applicable Standards:

Switchboards are designed to conform to the requirements of the following Standards:

⇒ IS/IEC 61439 / 60439- Factory Built Assemblies of Switchgear and Control gear.

⇒ IS 375 - Marking and Arrangement for Switchgear Bus bar etc.

⇒ IS 4237 - General requirements for Switch gear & Control gear.

⇒ IS 2147 - Degree of Protection provided by enclosure for Low Voltage Switch gear & Control gear.

⇒ IS 2516 - Air Circuit Breakers of voltages not exceeding 1000V AC

⇒ IS 4064 - Fuse Switch and Switch Fuse units for voltage not Exceeding 1000V AC

⇒ IS 9224 - H.R.C. Fuse Links

⇒ IS 2705 - Current Transformers

⇒ IS 1248 - Indicating Instruments

⇒ IS 722 - A.C. Electric Meters

⇒ IS 3231 - Electrical Relays for Power System Protection

⇒ IS 6875 - Control Switches & Push Buttons

⇒ IS 10118 - Code of Practice for Selection, Installation and Maintenance of Switch gear and Control gear

⇒ IS 13947 - Low Voltage Switch gear and Control gear – Contactors & In the absence of specific Indian Standard Specifications, International Electro-mechanical Committee Specifications are followed.